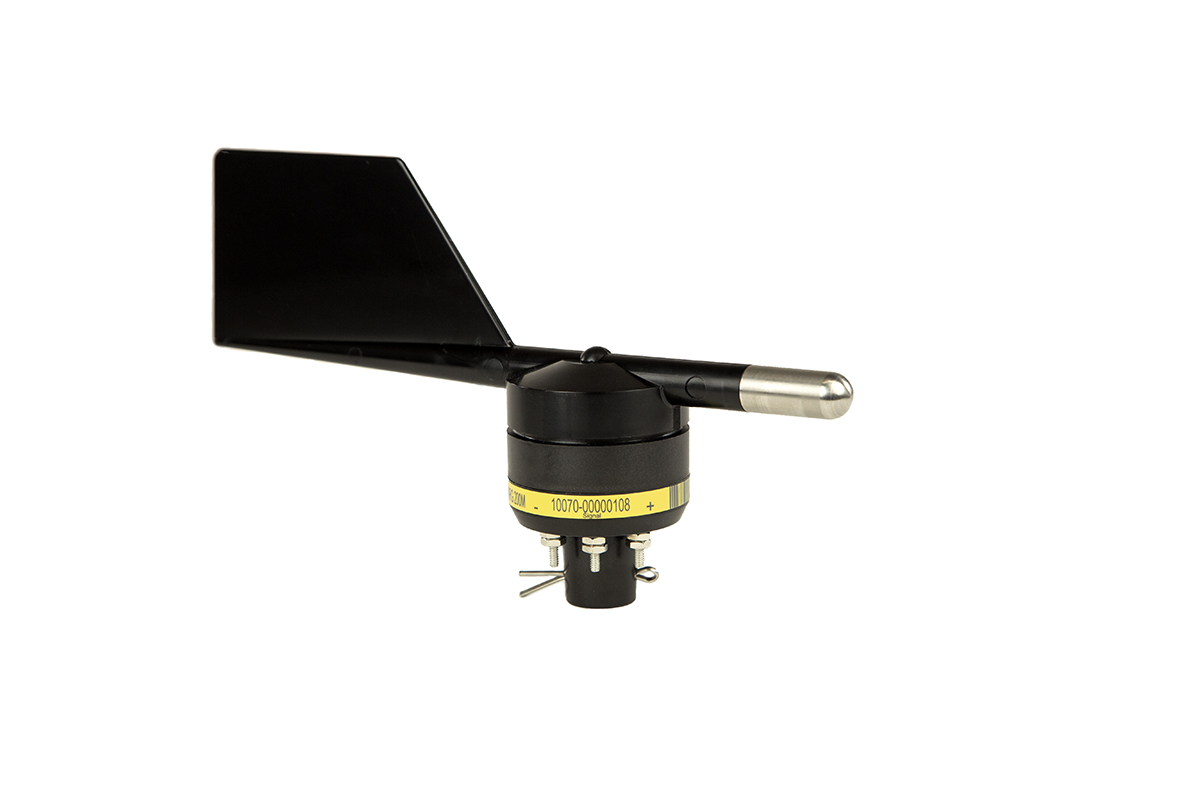

NRG 200M Wind Vane

The 200M Wind Direction Vane features a remarkably accurate sensing element that produces no dead band, achieving lower uncertainty and 360° continuous measurement.

Details

NRG Systems’ 200M Wind Direction Vane brings significant upgrades to the proven design of our 200P Wind Direction Vane.

New in the 200M:

- No Dead Band: The 200M has 360° continuous measurement, whereas the 200P has an 8° max. dead band centered on 0°.

- Reduced Sensor Uncertainty: The 200M's sensor uncertainty is ±1.6° across virtually its full range, whereas the 200P's sensor uncertainty outside the dead band region is ±4.3°.

- Improved Vane Orientation Precision and Repeatability: The 200M's improved mounting system makes it easier to precisely determine sensor orientation once installed on a boom.

- Firmer Mounting Connection: The 200M's new mounting system enables a firmer connection between the vane and mounting boom, making it less likely that vane orientation will drift over time.

- Improved Protection Against Water and Dust Ingress: The 200M's bearing and electronics capsules are fully sealed against water and dust ingress, making it less likely that corrosion or dust will damage the sensor over time.

- Transparent Records of Sensor Response and Quality: Factory calibration certificates with sensor-specific scale and offset values will be available at no extra cost. Download Calibration Report

MAINTAINED FROM THE 200P:

- Proven Aerodynamic Performance and Robustness: The 200M utilizes the same black, UV-stabilized injection molded plastic vane wing and sensor body that the 200P has been proving in the field for decades.

- Easy Sensor Traceability: Individual unit serialization makes it easier to keep track of your wind vane's unique history and ties it to its sensor-specific slope and offset values determined during the manufacturing process or in a wind tunnel.

- Easy Compatibility: The 200M’s simple voltage output is compatible with all industry-standard data loggers, including

- NRG's suite of data loggers.

- Low Power Draw: With a current draw of <500uAmps on SymphoniePRO wind vane channels, there is no need to increase the size of the standard power supplies you use today to accommodate the 200M.

PLEASE NOTE: A wind tunnel calibrated version of the sensor is also available. Wind tunnel calibration serves as an additional quality check and record that an individual wind vane is performing normally prior to installation on a met tower. A physical calibration report is included with each calibrated sensor. The calibration procedure is based on the following standards:

- IEC 61400-12-1: Power performance measurements of electricity producing wind turbines

- IEC 61400-12-2: Power performance of electricity producing wind turbines based on nacelle anemometry

- ISO 16622: Meteorology - sonic anemometers/thermometers

- ASTM 5366-96: Standard Test Method of Measuring the Dynamic Performance of Wind Vanes

Benefits

- Same vane and body design as 200P ensures seamless transition to 200M

- Like the 200P, the 200M is compatible with NRG's suite of data loggers

- Field-tested materials for long-lasting durability

- New magnetic encoder-based signal generator means accurate data are available in all wind directions

- Improved mounting precision lowers measurement uncertainty

- Factory calibration certificates with sensor-specific scale and offset values reduce uncertainty caused by sensor-to-sensor variability

Recommended Items

Specificiations Print Specs

Product Support

Customer Service

+1 802-482-2255

Mon – Fri: 8:30am – 5:00pm Eastern Time (GMT-5)